Training experts in digital manufacturing and innovation in Uruguay

Fab Lab Barcelona to co-direct and curate a new specialization in Digital Manufacturing and Innovation at UTEC (Universidad Tecnológica del Uruguay).

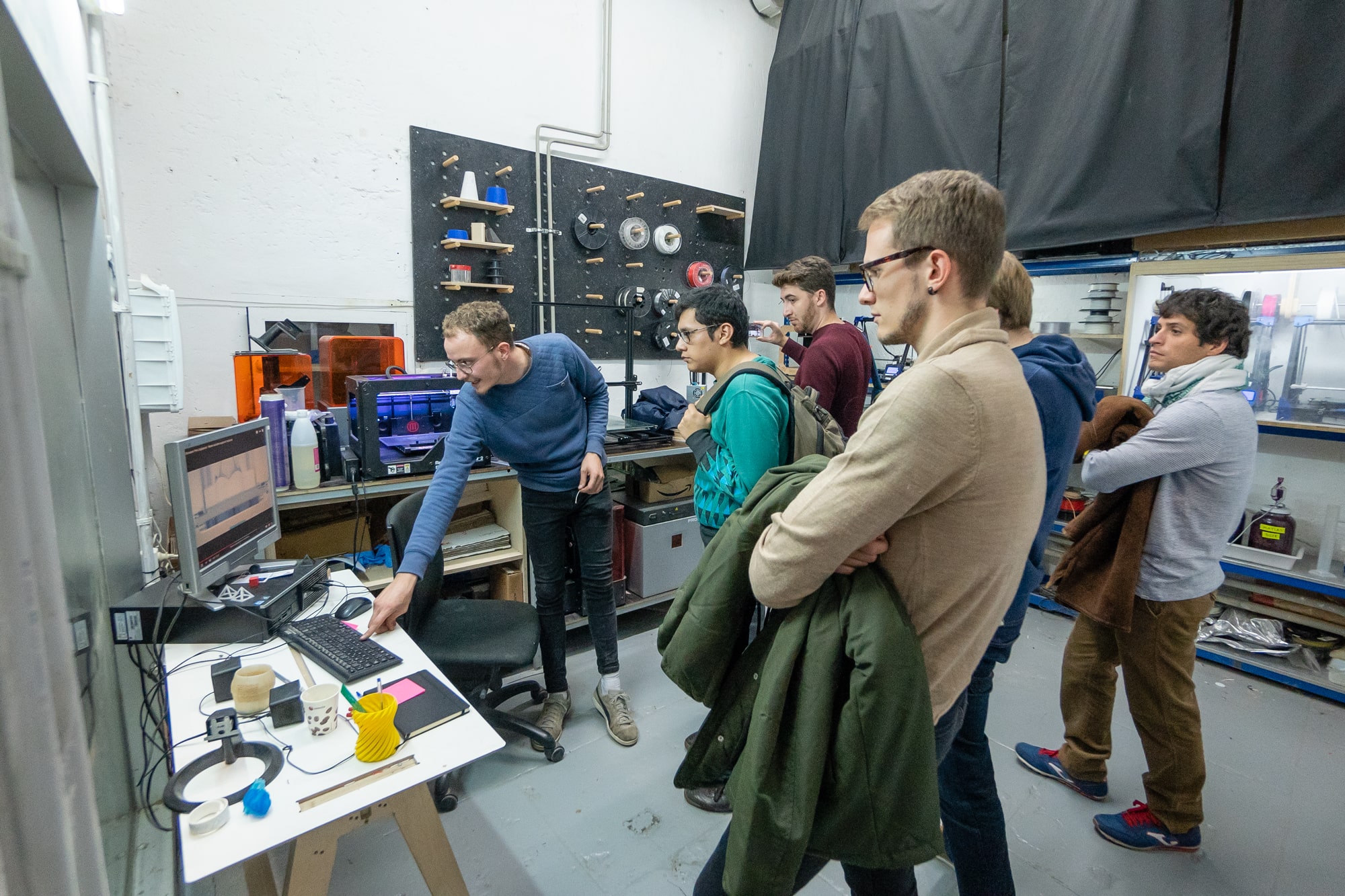

The benefits of digital fabrication are clear: Intelligent and networked methods and tools enable more flexible manufacturing and rational use of resources which in turn increases profitability, strengthens competitiveness and improves sustainability. For this reason, digital fabrication technologies have gained increasing relevance in all industries and are therefore constantly gaining importance in the academic field.

The specialization

Tackling this matter, Fab Lab Barcelona is co-directing and curating a new specialization at UTEC (Universidad Tecnológica del Uruguay). Starting in August 2021 the course lasts from 10 to 12 months with a weekly workload of 15 to 20 hours.

Participants learn the skills to address complex production challenges and are trained to design, prototype, and evaluate viable and efficient technological solutions.

In order to contribute to sustainable development, the program focuses on co-creation and uses open innovation methodologies and digital fabrication tools.

The blended learning program will include courses, workshops and online seminars such as Entrepreneurship and Innovation Workshops and a 3-day intensive in-person workshop in Uruguay.

The participants will study under the guidance of leading experts from Fab Lab Barcelona and UTEC and will be able to complete internships in Digital Labs (online or face-to-face in Uruguay).

Deepening Module

Professors of Fab Lab Barcelona will teach the “Deepening Module” (MP) which includes an introduction to Digital Manufacturing and Innovation/Innovative Project, Prototyping and Digital Transformation. Thereby students will be introduced to the current context of Digital Fabrication and Open Innovation and its applications in production and design as well as in the prototyping process. They will be introduced to tools for the validation of a project through the prototyping of an idea and get an insight into the current context of digital transformation, paving the way for the export of design services, prototyping and evaluation of technology-based innovations with the assistance of digital manufacturing tools.

Requirements

With a special emphasis on multidisciplinary approaches, the program is aimed at professionals from different fields such as design, industrial production, architecture, audiovisual production, engineering and related technical areas and thus aiming to establish digital technologies as an essential part of the future of fabrication.

Click here for more information on the specialization and how to apply.

Registrations can be sent to [email protected]

The registration period ends on August 6th, 2021.