Digital Fabrication is transforming production and consumption

Produce local, send global

What is Digital Fabrication?

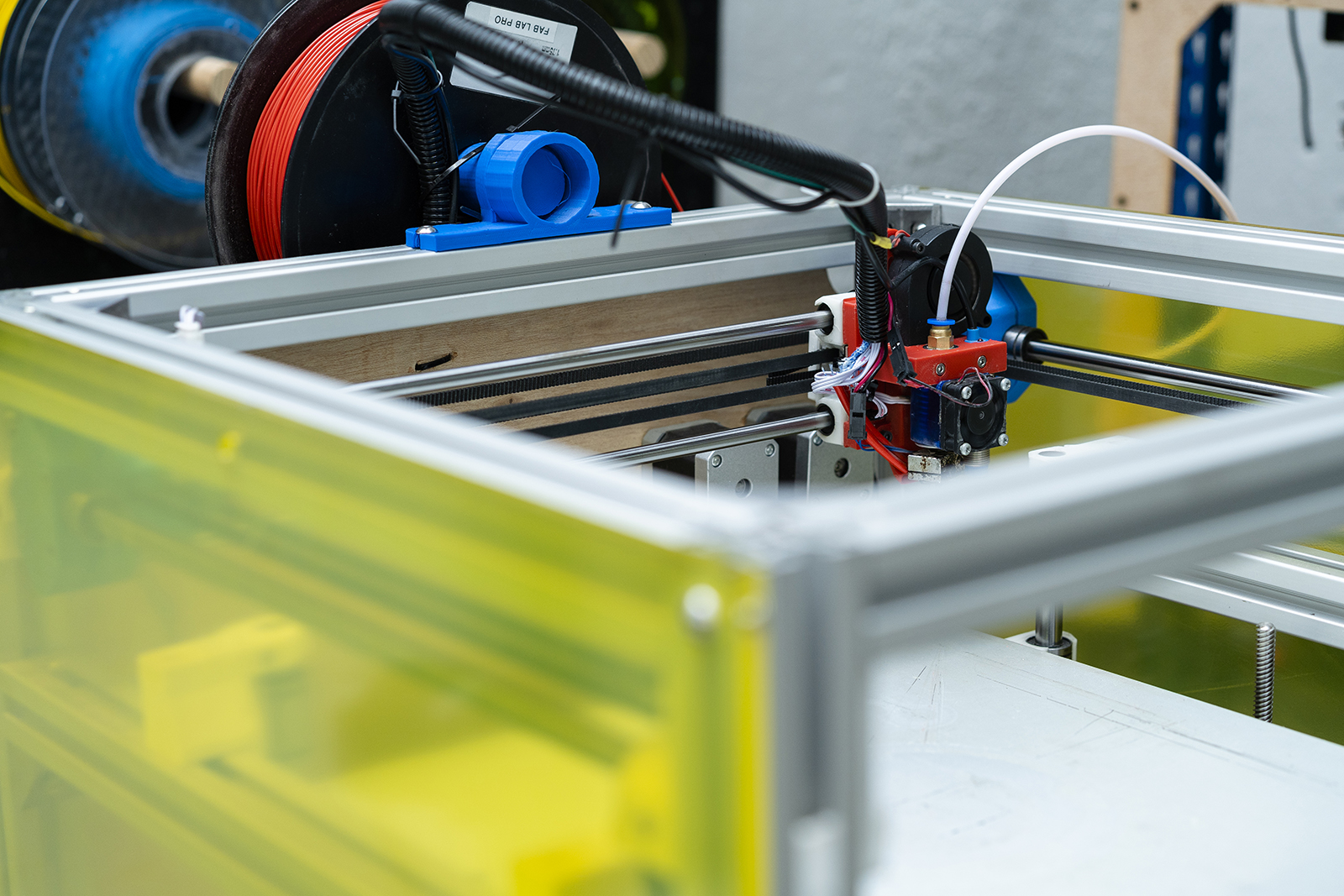

Digital Fabrication is the use of computer-aided design (CAD) programs to cut, print or laser to create something with additive (3d printing) and subtractive (CNC, laser) manufacturing. The machines used to perform these tasks are usually a laser cutter, 3d printer or CNC. Machines for Digital Fabrication are often found in small-scale workshops, makerspaces and Fab Labs (fabrication laboratories). Currently, Digital Fabrication or Digital Modelling is most commonly known within the architectural realm, creating space for methods of rapid prototyping, new form and structural integrity (to see an extensive glossary on Fab Labs and any keywords which you have not seen or heard before, see our article on Fab Labs).

Where can I find Digital Fabrication?

Digital Fabrication is continuously pushing the boundaries for more mindful and sustainable design and can be commonly found in small-scale manufacturers, workshops, makerspaces and Fab Labs. Digital Fabrication can be accessed globally and digitally – via a whole host of online websites with open-source designs for you to download, make and manufacture anywhere. Open Desk is a “global platform for local making” – a well-known example of an open-source, online platform containing designs for furniture which can be cut on a CNC machine. Other sites such as Wikifactory are social platforms for projects using Digital Fabrication – projects on Wikifactory range from DIY CNC machines to Farmbots and more.

The potential of Digital Fabrication

Digital Fabrication has huge potential globally. This ranges from the economic potential it provides for small-scale manufacturers, to the option of personalisation of products and working towards a more sustainable urban model of production and consumption which is accessible for a much greater range of people.

click to tweetDigital Fabrication creates the space for you to think about how you really imagine the product to look, feel, or work like.

Modularity

Digital Fabrication creates small, modular units – designed with standardized units/dimensions. This allows for ease of assembly, placement, use and repair. This maximises productivity and is cost-effective as separate design pieces can be cut and assembled later, rather than cut into one single piece.

Rapid prototyping

Digital Fabrication also allows rapid prototyping tests and mockups of final designs. This allows for changes to occur during the design process, rather than at the end, preventing excess waste or loss at the end. This also ensures a higher quality product, due to continuous testing during the prototyping process. The product testing reduces the error margin and therefore, the end functionality of the product.

Personalisation

Furthermore, when designing your own product, Digital Fabrication creates the space for you to think about how you really imagine the product to look, feel or work like. For example, in designing a modular kitchen workspace, extra elements can be 3D-printed or cut to suit your needs.

Repair

Not only does Digital Fabrication change the way products are designed and made, but it also extends the lifespan of products which may have originally been cast to the bin. Digital Fabrication allows the repair of products – whether it be a new 3D-printed leg, handle, hook or joint.

Materiality

Digital Fabrication also opens up new methods of design which uses less material and produces less waste, therefore being most cost-effective at the same time. This can be through creating joints that do not require a glue to hold the pieces together (press-fit joints) and also through using as much of the material as possible.

Automation

Partial automation of the production process means that manufacturers can save on time-intensive and heavily-consumptive tasks. This reduces hard, physical repetitive labour for manufacturers and opens up new possibilities for developing designs, learning new skills or product iterations.

Fab City – sending data globally, making locally

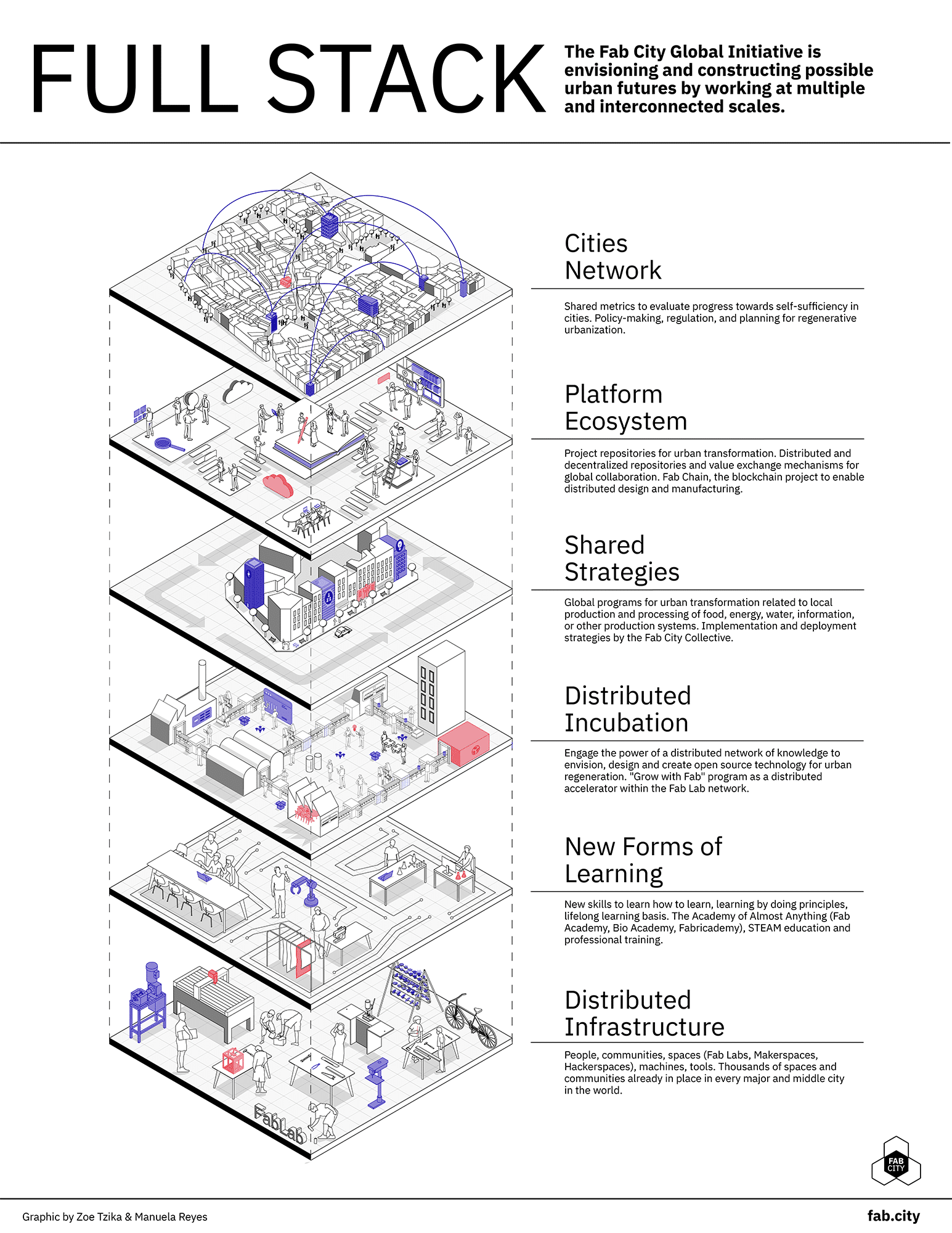

The Fab City Global Initiative started in 2014 when the then-mayor of Barcelona signed the pledge for cities to produce everything they consume. This means that data (atoms) move globally, whilst products stay local. Digital Fabrication is therefore inherent to the Fab City movement – creating space and need for local manufacturing rather than mass-manufacturing. When paired with the open-source movement, Digital Fabrication is a powerful tool which has the potential to change the way which we produce and purchase products.

click to tweetDigital Fabrication is continuously pushing the boundaries for more mindful and sustainable design.

Digital Fabrication can also be empowering for small-scale manufacturers due to greater control over the production process, rather than having to rely on large-scale manufacturers. In the Fab City full-stack, Fab Labs provide the distributed infrastructure for innovation in digital fabrication. This means that, in addition to the machines, Fab Labs contain the network and knowledge resources to inspire and educate projects.

Scalability

This method of manufacturing is scalable – the consistency of CAD programs and the CAM machines means that knowledge transfer between places globally can flow easily – e.g. if you were to work in one Fab Lab in Chile and then move to a Fab Lab in Madrid, you would quickly be able to adapt to the machines in the new environment.

Digital Fabrication has already highlighted it’s huge potential for manufacture in the world and has potential for more. The combination of physical, digital fabrication sites with open-source, online platforms means that anyone can make (almost) anything, anywhere. When considering the future of cities, this is an important tool we will need to transform the way we produce and consume. We already know that our currently linear model is intrinsically unsustainable, we have the tools to change, we just now require a collective behaviour shift to begin to utilise our proximity to each other and the tools to make things.

Interested in learning more about Digital Fabrication?

- Study MDEF / Fab Academy Barcelona

- Make with Wikifactory

- Find a Fab Lab or makerspace near you

- Discover local manufacturers and materials near you with the Make.Works platform