The city as a source of raw materials and circular opportunities

A good practice brought to life by Fab Lab Barcelona

Right in the heart of our bustling cities, where buildings are being renovated and many fairs and conferences are taking place, there’s a hidden treasure trove of materials just waiting to be reused. Join us as we dive into the world of circular economy and discover our approach to foster a circular and productive city.

Imagine our cities as open mines, but instead of digging for minerals, we’re uncovering existing materials and finding innovative ways to put them to use. In this perspective, urban areas become valuable warehouses filled with raw materials just waiting to be tapped into.

In this blogpost, we’re going to explore a practical example of how Fab Lab Barcelona led a participatory process to recover wood strips and give them a second life: what might have amounted to wasted kilograms of wood were converted into modular wooden structures for events and exhibitions.

Understanding the local context

To understand the potential of circular wood production in Barcelona, Fab Lab Barcelona began focusing on the district of Sant Marti, taking a panoramic view of urban wood waste, as well as a close-up deep dive into local wood resources within our community’s businesses.

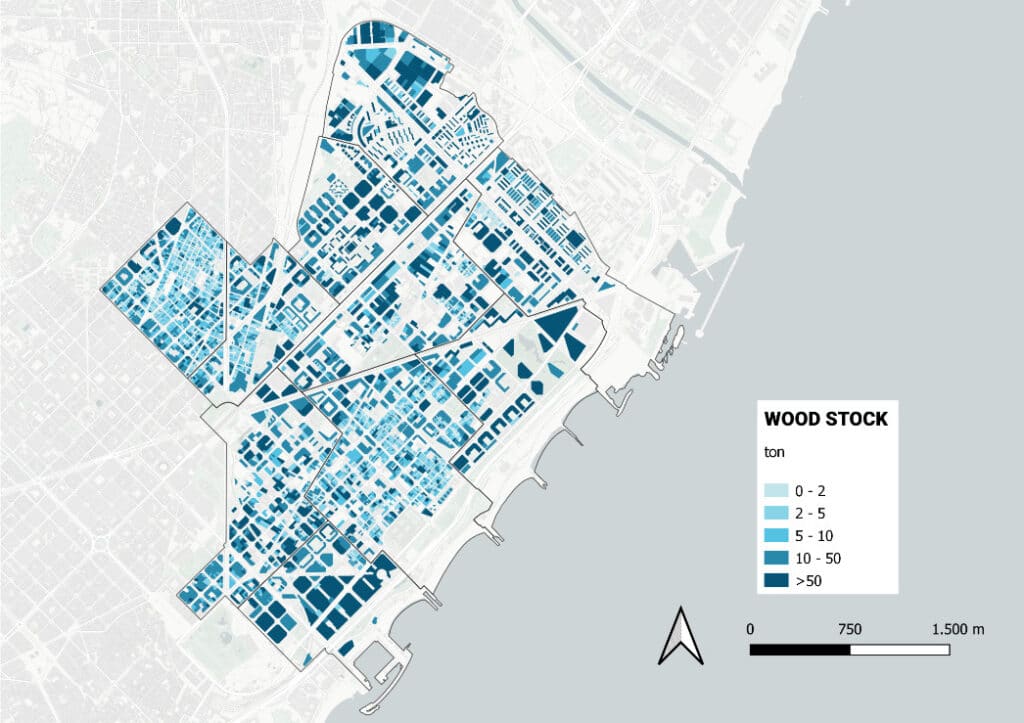

From a top-down perspective, a contextual picture of wood stocks in the Sant Martí district was developed through an Urban Mining analysis in collaboration with the Metabolic Institute. It was calculated that a total of 168 kilotonnes of existing wood is present in the selected buildings of Sant Martí (equivalent to enough material to build 258 Eiffel Towers!). Check more about this study here.

Following a bottom-up approach, local producers, makers, creative spaces and local businesses were interviewed and listed in Make Works Catalonia, an online platform that aims to make local manufacturing more accessible. During each interview and site visit with local manufacturers, the local team identified many types of materials used for production, waste materials generated, listed their machines, processes, traditions and other capacities and skills. The aim of this step was to identify manufacturers’ potential role in improving material circularity.

The information gathered during these visits was consolidated alongside input from various local actors and existing initiatives, all integrated into a dedicated map of Barcelona’s productive sector.

Identifying potential future scenarios

By mapping existing initiatives, small businesses, manufacturers, and digital fabrication spaces eager to collaborate with materials salvaged from our city, Fab Lab Barcelona has unlocked a range of exciting possibilities for local wood reuse. Dive into this interactive presentation to uncover opportunities for promoting wood and wood waste circularity in areas such as education, material innovation, large-scale production, and even urban gardening.

Giving a second life to leftover materials

Barcelona is one of the leading cities in the world in terms of the number of international conferences and trade fairs, hosting a multitude of these events throughout the year. These gatherings, however, often rely heavily on temporary structures constructed from materials like wood, metal, or plastics, only to be used for a short period of time. While certain initiatives have been initiated to enhance material circularity within the city, the efficient storage and reuse of these resources still pose significant challenges.

Following its commitment to explore circular economy principles, Fab Lab Barcelona at IAAC succeeded in recovering more than 100 discarded wood strips from the Mobile World Congress 2023, repurposing them into modular wooden exhibition stands.

This remarkable undertaking not only underscored the vast potential of urban materials but also embraced a participatory approach. Designers and interested citizens, keen to explore the skills of traditional carpentry and digital fabrication, came together to breathe new life into these neglected resources. Together, they demonstrated that a shared commitment to sustainability can yield remarkable and transformative results.

Check out some images from the making process!

Valorizing the productive identity of Poblenou

The wooden structures were created for the Poblenou Fàbrica/ Fabrica Exhibition, which took place at Ca l’Alier in May 2023 in the context of the European project CENTRINNO. Chronologically, the exhibition aimed to be an archive of the productive neighborhood of Poblenou and its trajectory over the decades. For this reason, an evolutionary portrait was presented, celebrating its rich industrial heritage by honouring local manufacturers and artisans, showcasing their stories and exhibiting the tools they use for production. The exhibition also envisaged a future reimagined as a space of transformation, driven by innovative approaches to education. Read more about it here.

Materials and steps for the creation of the wooden structures

Bill of Material

- Wooden Filler

- Wood Clamps

- Belt Sander

- Orbital Sander

- Linseed Oil

- Tee nuts

- Screws

- 7.5mm Drill Bit

- 7mm Drill Bit

- Swivel wheel with brake

- Wooden Slats: 5cm wide and 2.10 length

- Foam Painting Roller Brush

- Paper Towels

Steps

Step 01. Disassembling the Pieces

Begin by disassembling the previously created structures at the workshop. Choose wooden pieces with fewer holes and imperfections, ensuring they are longer than 2.10cm. Separate the pieces.

Step 02. Make the Cuts

After selecting the wood, cut each piece to its respective size (210cm – 114cm – 132cm). For the 30cm supports, cut them at a 0-degree angle using a wood cutter.

Step 03. Drilling holes

Once the wood is cut to size, follow these steps for piece 01:

- Drill a hole using a 20mm paddle bit.

- Then, pass a 7mm drill bit through the same hole to accommodate the screws.

- Drill holes for the wheels: Use 2 screws measuring 70mm.

Step 04. Filling Holes

Since recycled wood is being used, cover all previous screw holes and potential gaps in the wood grain with wood filler, making the surface as smooth as possible. We recommend allowing it to dry for approximately 3-6 hours before sanding.

Step 05. Sanding the Surfaces

Once the filler is dry, use wood clamps to secure the wooden slats to a flat surface for sanding on all four sides, including the tops and bottoms. Sand the wooden slats in the following order:

- Optionally, use a router to round the edges of the slats, starting 5 cm after the corners.

- Use an 80-grit sandpaper with a belt sander or orbital sander on all four sides.

- Finish with a 200-grit sandpaper for a polished look.

Step 06. Coating

After sanding, clean the wood with compressed air to remove any dust residue. Place the slats outdoors on trestles and apply several coats of linseed oil (for a natural finish and weather protection) using a roller. After two coats of oil, wipe off any excess with paper towels. Let the pieces dry overnight, but they can be ready in 3 to 5 hours.

Step 07. Assembly

Once all the wood pieces are ready and dry, assemble as follows:

- Attach the brackets to the two inner legs using a hammer.

- Screw the inner leg to the top of the structure using two 70mm screws on each side.

- Connect the outer leg to the inner leg using a black screw and washer on each side.

- Add the supports.

Structure 02: Tables

For the wooden tabletops:

- Start with 1.5cm thick boards, which have been processed through a CNC machine with holes as per your design.

- After CNC cutting, repeat the sanding process in the same order (router for outer edges, 80-grit sandpaper, 200-grit sandpaper).

- Finish by applying linseed oil.