RESERVIST

Repurposing manufacturing lines for providing medical products and services in case of spiking demand times.

The Challenge

Set up a concept, methodology and practical supply chain to respond to crisis medical needs, PPE and other equipment.

The Solution

Bring a concept from military environments and humanitarian relief so-called ‘reservist cells’, that can be activated within 48 hours.

Type of Project

Innovation Action for Industrial Leadership in advanced manufacturing and processing funded by European Union’s Horizon 2020 programme under Grant Agreement 101016041.

Project Outputs

A backbone network of core companies for manufacturing and testing, an extended network for further capacities, a digital coordination platform and a pool of experts from the companies of the network.

The Project

How can industries quickly change their production lines to manufacture medical solutions in 48 hours? RESERVIST calls for the creation of resilient networks of suppliers, manufacturers, notified certification bodies and distributors in response to the current COVID-19 pandemic.

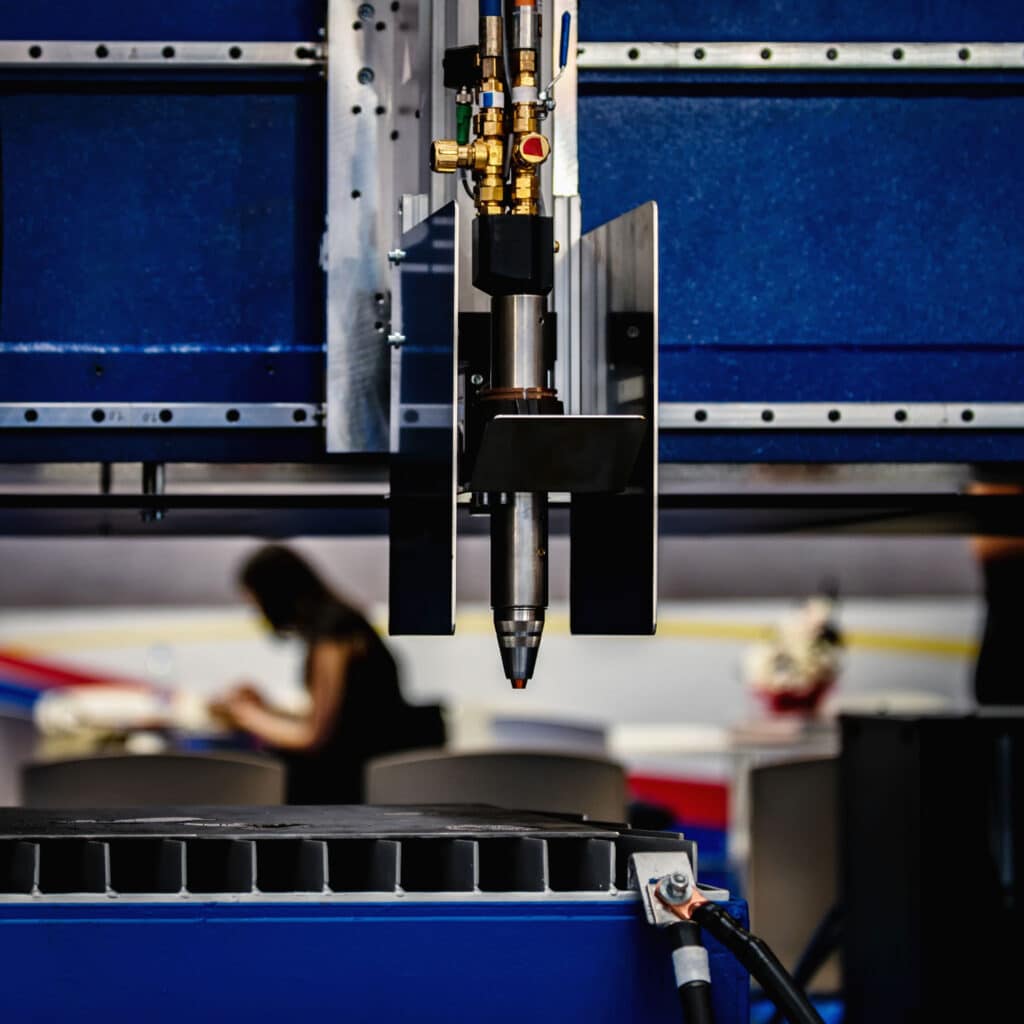

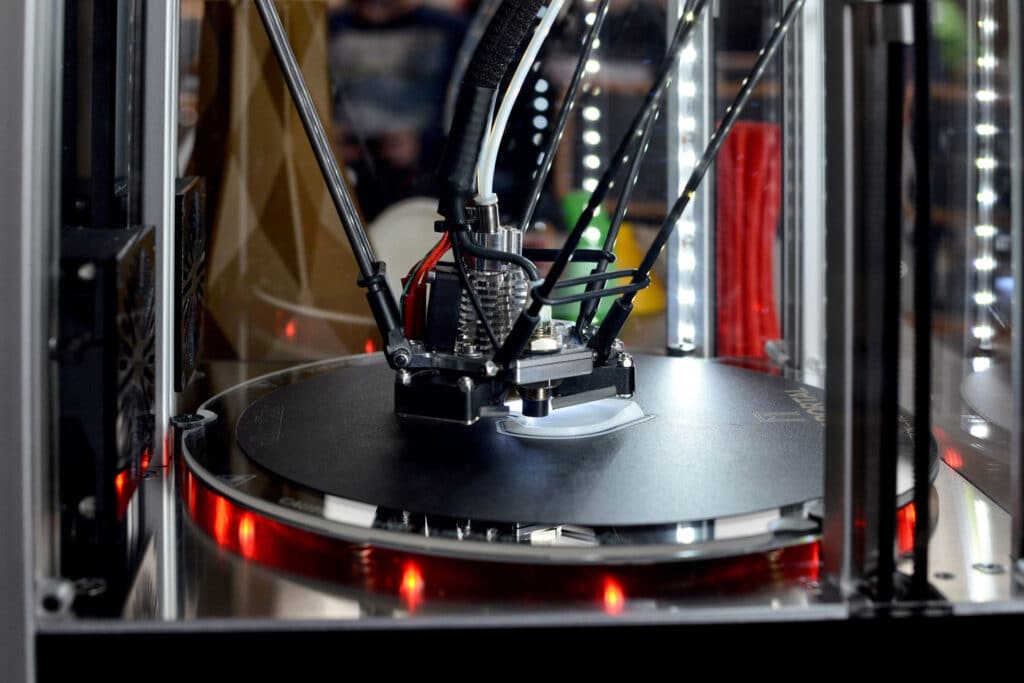

Fab Lab Barcelona at IAAC, together with the other European partners, aims to repurpose manufacturing lines to respond to crisis needs. The consortium consists of 17 partners from 7 EU countries and is coordinated by Centexbel, the Belgian research centre for textiles and plastics.

The ongoing COVID-19 crisis has shown that several types of PPE and medical equipment are crucial, including the ability to deploy them rapidly. Because of cost factors, these products, or at least critical components for them, are often produced outside the EU. Once things normalize, there will be a large pressure to return to that situation. Therefore, it is a real challenge to set up a concept, methodology and practical supply chain, especially since for large scale manufacturing one needs tapping into existing lines at commercial companies.

RESERVIST aims to establish a network of ‘reservist cells’ to activate surge manufacturing when standard production lines cannot respond to the demand for medical products. The concept starts from what is currently used in military environments or also in humanitarian relief, where ‘rapid response teams’ are constantly on stand-by, ready to be activated in case of a need.

In times of crises, ‘reservist cells’ can be activated within 48hrs to switch to manufacturing medical products and services that are spiking in demand. Such a ‘reservist cell’ will consist of:

- a backbone network of core companies for manufacturing and testing

- an extended network for further capacities (local provision, packaging, distribution, customization,…)

- a digital coordination platform

- a pool of experts from the companies of the network.

These cells will become operational in case of an emergency/pandemic but to make economic sense, the same approach of rapid flexibility and adaptability will be used to deal with surging demand in ‘normal circumstances’.

Our Contribution

Create blueprints for replicating the RESERVIST Network for future emergency scenarios that can further support industries around Europe. This approach will allow to expand the network to very different locations, increasing the society ́s response resilience, by enabling (SME) companies to deal with different pandemic scenarios.

We will tap on the fab lab network for enabling distributed manufacturing of medical solutions.

Who is it for?

Industries, Technological Research Centers, Startups, Policy makers, Providers.