The key role machines play in our research

Making 'almost anything' is only possible with our machines that do almost everything.

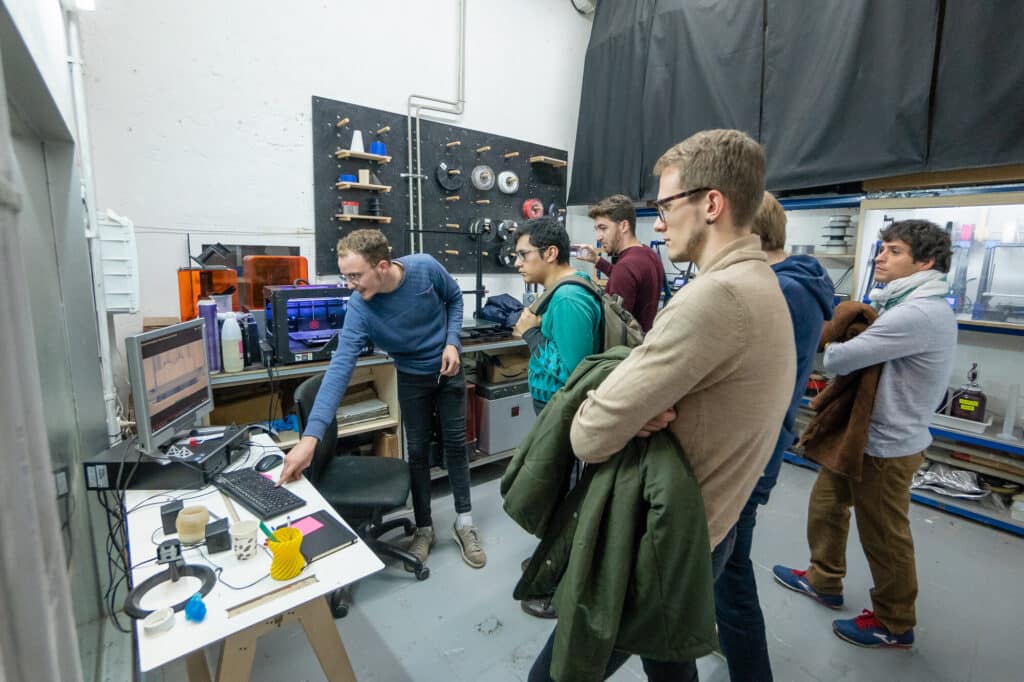

A fab lab without machines is like a kitchen without knives, sure you could make things, but it’s going to be a bit difficult. At Fab Lab Barcelona our researchers, designers and students use our machines every day to fabricate a seemingly limitless amount of creative projects, prototypes and even other machines. Nearly everything we do takes advantage of our access and ability to fabricate using a variety of technical equipment, from the very basic vinyl cutter, to advanced 6-axis robotics capable of doing everything from 3D printing clay to painting.

In this blog post we will take a look at our essential equipment, how we’re building new open-source machines in our fab lab, how we’re teaching others to use specialty equipment and our academic programs taking full advantage of our facilities.

What does it take to make ‘almost anything’?

At Fab Lab Barcelona we follow the “node” model of Fab Academy, based on Neil Gershenfeld’s Center for Bits and Atoms rapid prototyping course at MIT. This means that we have a core set of machinery that allows users of our lab to produce anything using open-source designs at our node (fab lab) or one of various other distributed nodes around the world. This machinery includes but is not limited to:

- 3D printers

- Laser cutters

- Vinyl cutters

- Desktop sized precision (micron resolution) milling machines

- Large scale CNC machines

With these essential machines, students in our various academic programs are able to create almost anything. In recent years, we have been able to expand our offerings in the lab to include plastic recycling machines, advanced robotics machinery as well as various non-plastic 3D printing technologies. In addition to this we have a number of woodworking hand-tools and metal fabrication technologies.

How does an open-source ethos influence our attitude toward machinery?

At Fab Lab Barcelona we follow an open-source ethos, meaning that our designs and many of the designs our students create are meant to be improved and iterated by others. We take this same attitude toward the types of machines we select to use in the lab, and also ensure that any design improvements we make to our own machines are uploaded and shared in a publicly accessible manner.

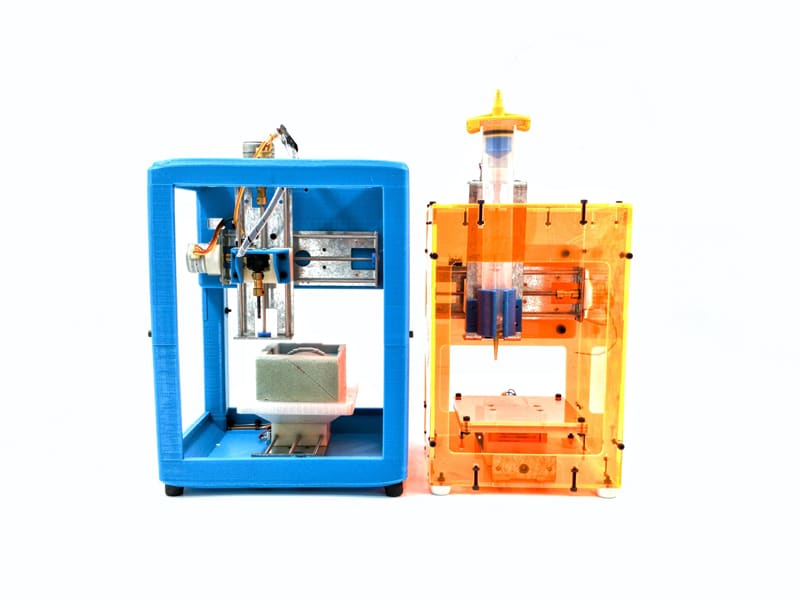

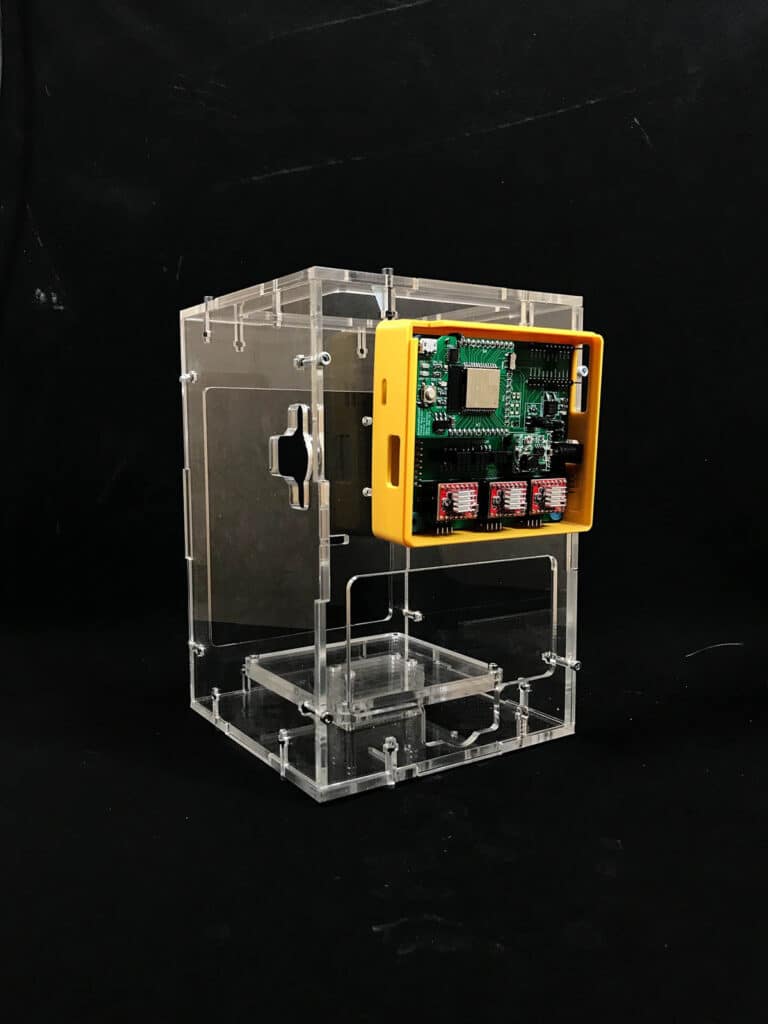

The Simple Personal Mini Lab (SPML) machine

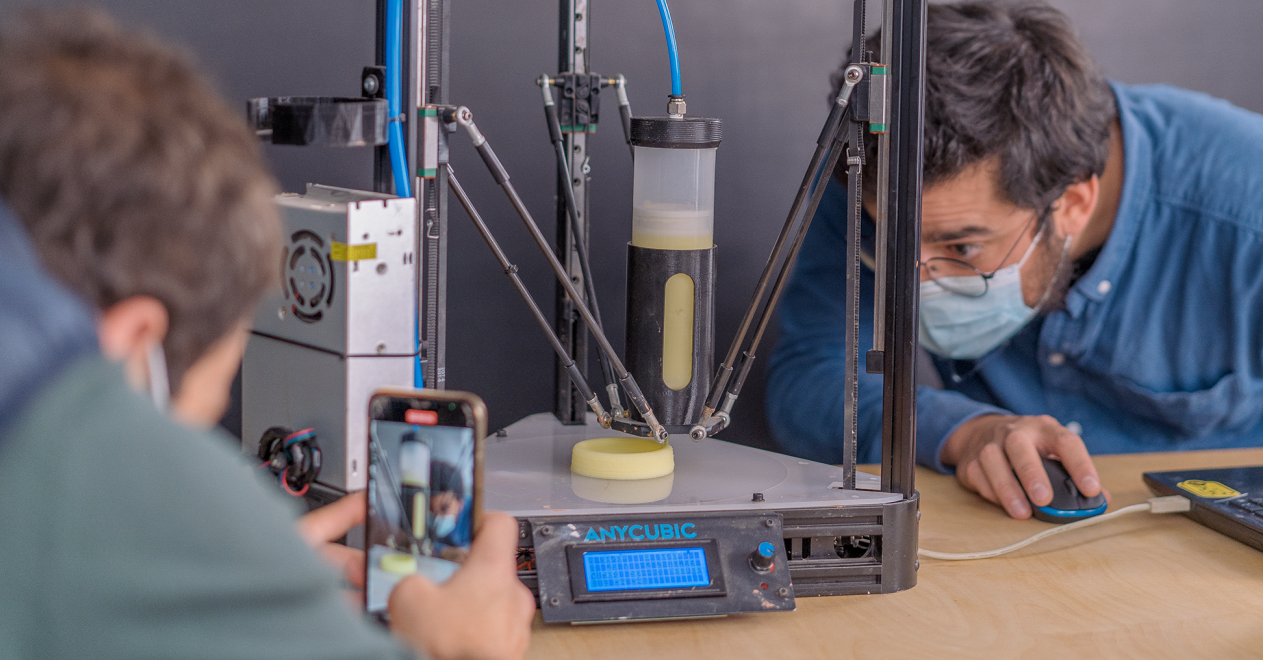

With our core sets of machinery, we are also able to create new machines – think 3D printing parts to make a new 3D printer. During the COVID-19 lockdowns, our research teams worked quickly to develop a prototype for students to continue their work from home, the solution was an open-source machine, The SPML, which could be built entirely using the 5 core machines of the fab lab nodes. This machine which has both CNC and laser cutting capabilities is roughly the size of a 6 pack, costs around 60 euros to produce and can be made in any fab lab around the world.

Iterating Precious Plastic’s open-source machine designs

In addition to making our own open-source designs, at Fab Lab Barcelona we have also been able to iterate and improve other open source designs for machines. In particular we have worked extensively with the machinery developed by Precious Plastics to create our own set of tools. In keeping with the spirit of open-source and distributed design practices, these changes and improvements to their original designs will be shared with the public in the form of a github repository where anyone is free to fork (copy) and make their own changes and improvements to the design.

With this open-source machinery, anyone can create their own precious plastics machinery and begin the process of recycling plastics for new uses in their own local setting.

Training others to use machines in a distributed manner

Students in our academic programs such as Fab Academy, the Master in Design for Emergent Futures, Fabricademy and in our prototyping programmes and learning experiences for companies and organisations are all given in person instructions and tutorials on how to safely and effectively use the equipment in our fab lab to help them realise their ideas. In light of an increased need for distributed learning, we decided to both expand our availability to train trainers to use more advanced equipment such as multi-axis robotics, as well as create a series of video tutorials for anyone using equipment at home or in other various other fab lab nodes.

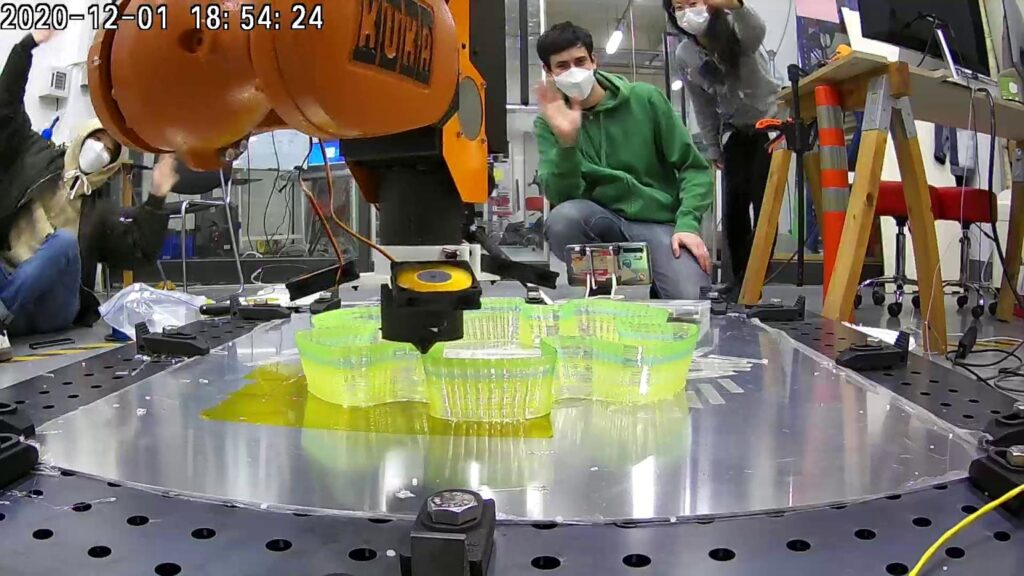

The Seoul Innovation Fab Lab advanced robotics workshop

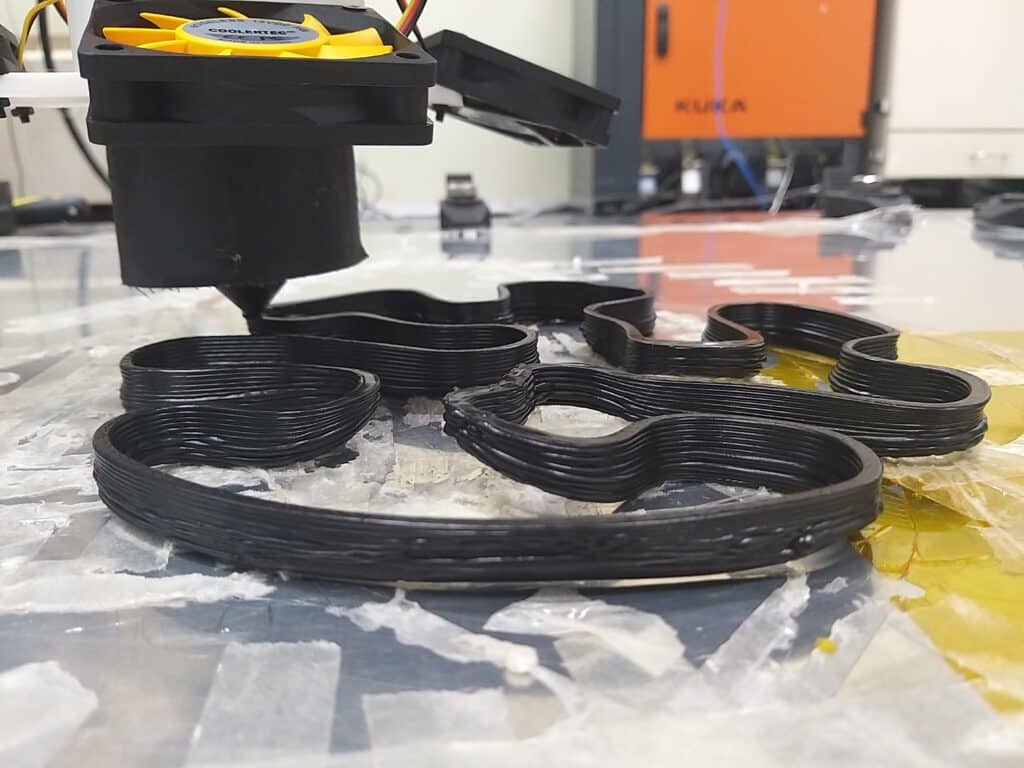

In the Fall of 2020, we partnered with Seoul Innovation Fab Lab (SIL) and the Advanced Robotics group at the Institute for Advanced Architecture of Catalonia (IAAC) to create a series of remotely taught instructional sessions to teach SIL faculty how to use their advanced multi-axis Kuka robotics machinery.

Following the interactive educational sessions, we then worked with SIL staff and faculty to facilitate a workshop with students in which they were taught how to use the robotics with the aim of 3D printing fully recycled plastic furniture. You can learn more about this series of workshops and how we facilitated the remote learning experience here.

Video Tutorials

We recently launched a series of video tutorials* of how to use some of our core machinery. These tutorials go through the ins and outs of using the equipment in a safe and effective manner.

*This series was made possible with the support of the ‘Ministerio de Cultura y Deporte de España‘ and is intended for public viewing as well acts as an additional resource for the education programs at Fab Lab Barcelona including, Fab Academy, the Master for Design in Emergent Futures, Distributed Design Academy, Fabricademy and more. The Distributed Design Academy is funded by the European Union’s Creative Europe program and the ‘Ayudas para la acción y la promoción cultural Ministerio de Cultura y Deporte de España 2020’ program.

Always continuing to iterate

Disruptive technologies are always presenting opportunities in a fab lab environment. We are on a mission to change the way we live, work and play in cities- and that means adapting rapidly to change and being a voice to bring about new change. We welcome designers, researchers, and students into our space to access our machinery, learn and help us grow together.

From open-source machines currently being developed in our FoodTECH 3.0 accelerator program, to exploring future technologies and ‘useless machines‘ in our Master in Design for Emergent Futures course, Fab Lab Barcelona will continue to not only embrace new machine technologies, but work toward open access and open-source improvements for all.